For this week's assignment, I chose to tackle the problem of "impossible to make (but possible to print)" by looking specifically at Mobius Strip Toriod Shapes. I started with a topological modeling program called "TopMod.py" which preserves mesh topology at its base. This allowed me to generate a topologically correct mesh version of a Mobius toroid. I then brought the project into Maya for detailing. I wanted to test the limits of the Polyjet printer, so I added spikes to the geometry. I then rendered and pushed an .stl out for the printer.

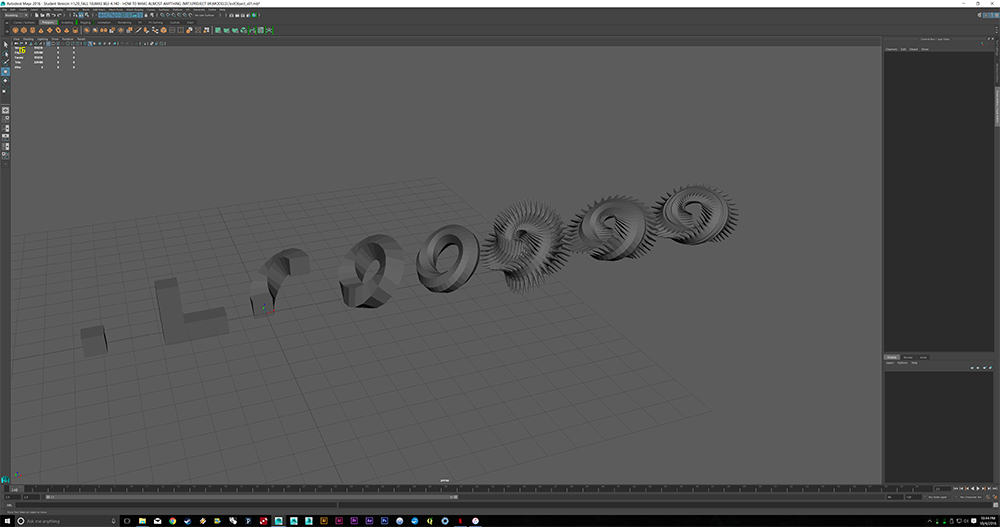

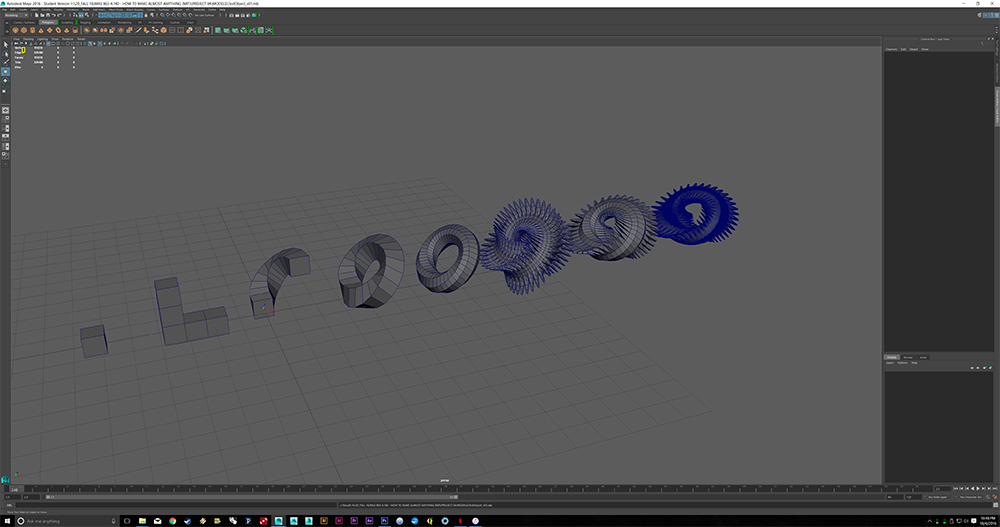

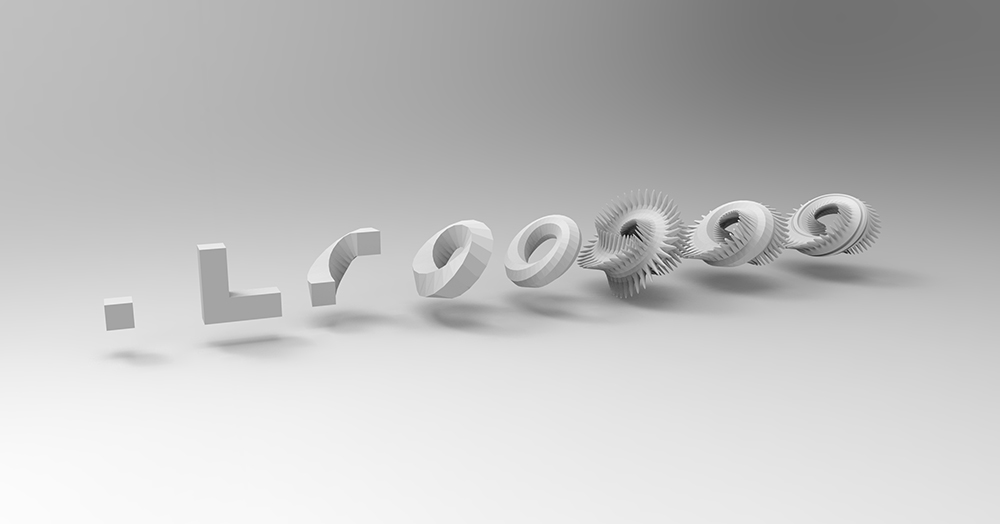

Pictured here is the process of generating the topologically correct Mobius torus.

Arrayed process part development.

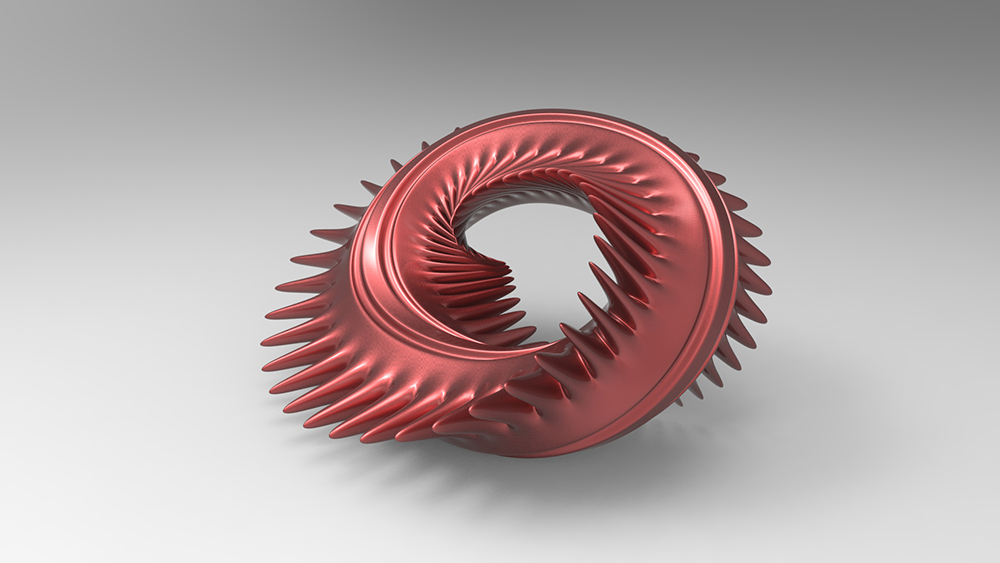

Final Rendering of Mobius Toroid

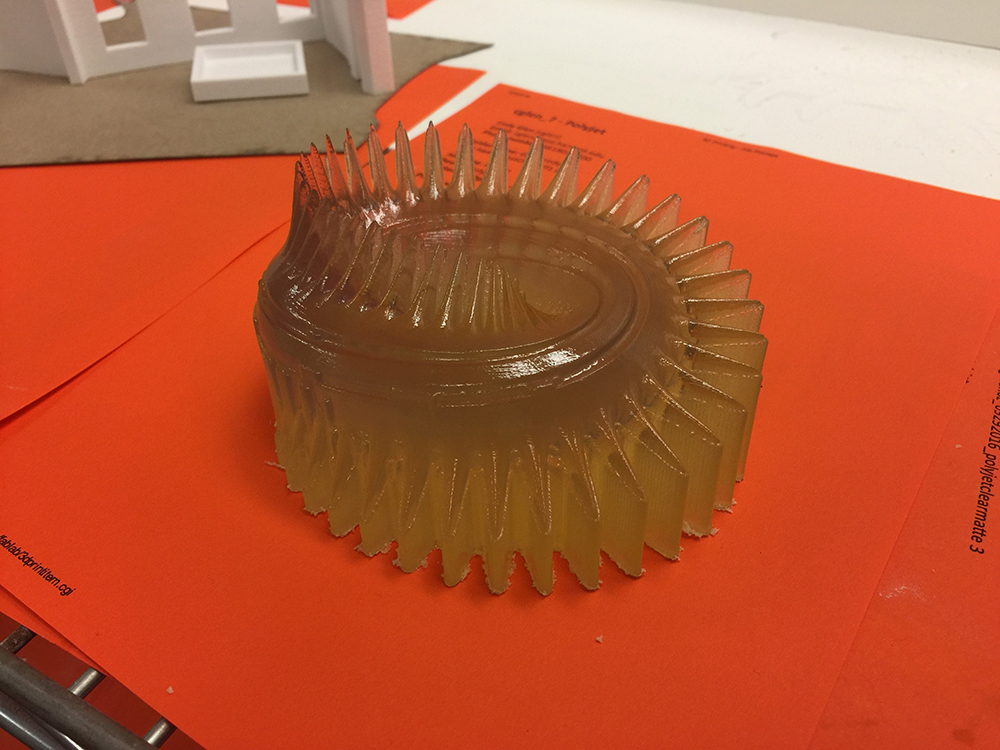

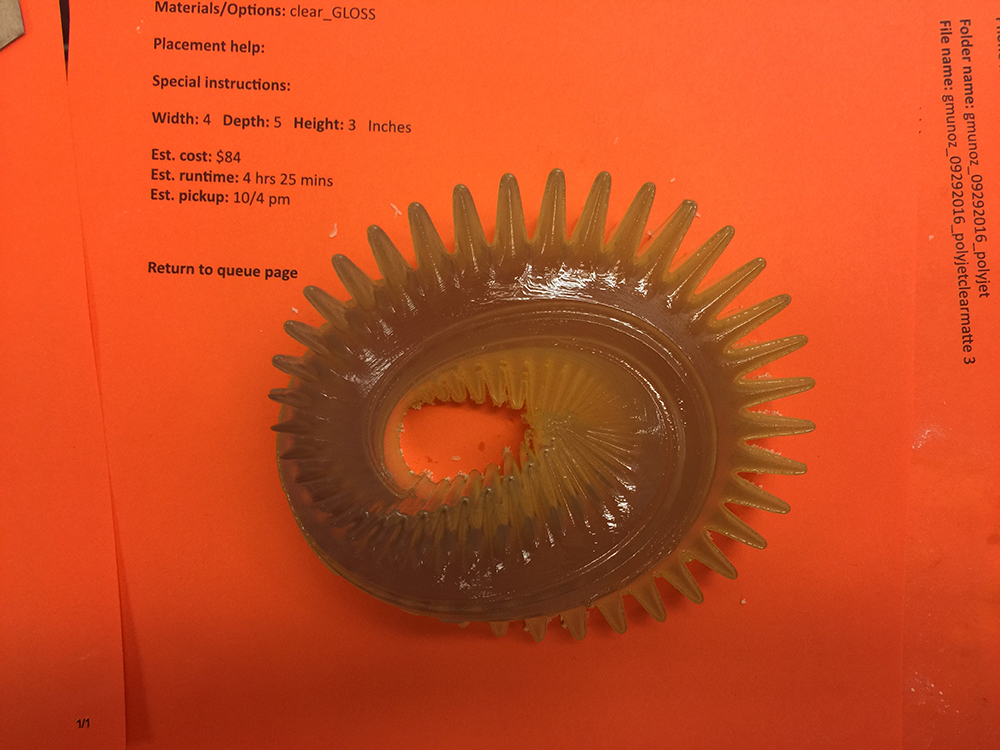

When the print comes out of the Polyjet, it's coated in a jelly-like support substance (and it kind of smells vaguely of cherries). I then weeded the part from the support by physically picking at it, then used a water bath and high pressure washer to remove the remaining material. I would normally sand and polish the final part, but I was pretty happy with the final outcome of the print.

Top View

Peeled part

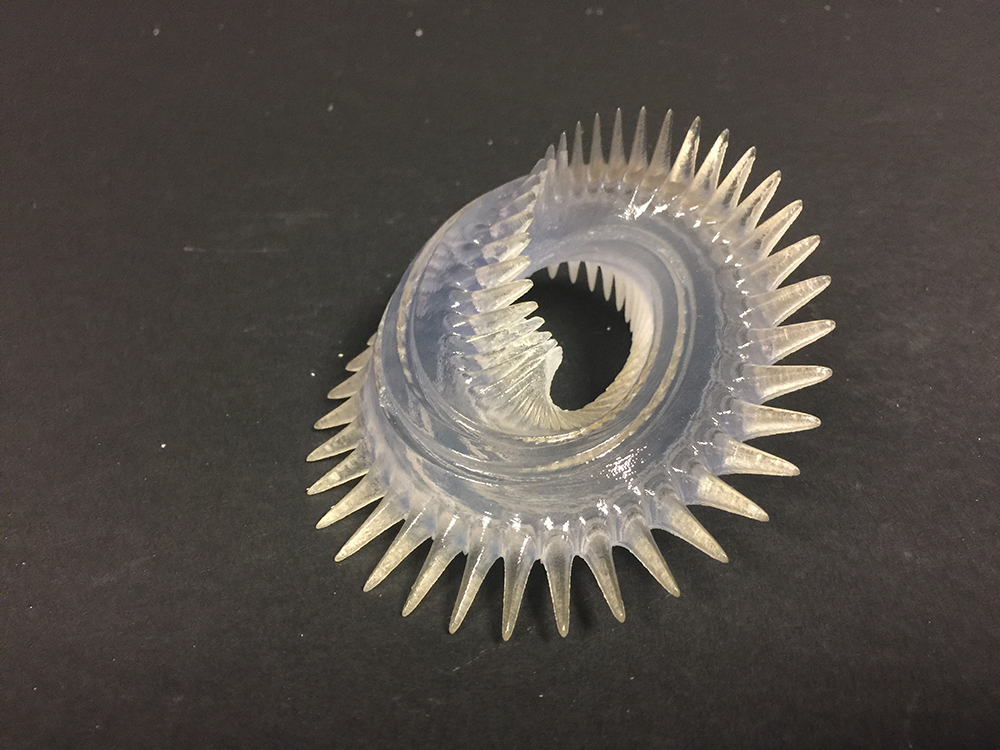

Here is the pressure washing stage. The water is foot-operated, but sadly only has one setting for pressure. You have to start with the part further away from the stream, and work your way closer. I've damaged prints before by blasting it too close with a really thin piece.

At this stage the part is close to being completely free from the support material. It's still necessary to go over the piece with a toothbrush to make sure all the support material is removed. This can be tricky with tight geometry.

Glamour Shot

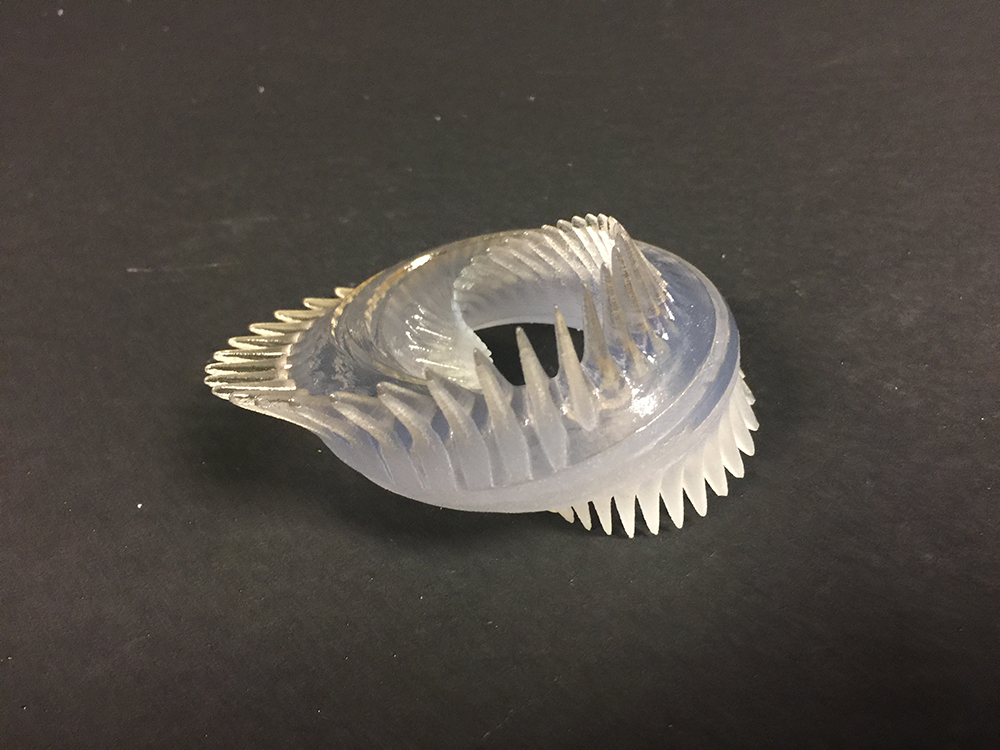

Glamour Shot

Glamour Shot

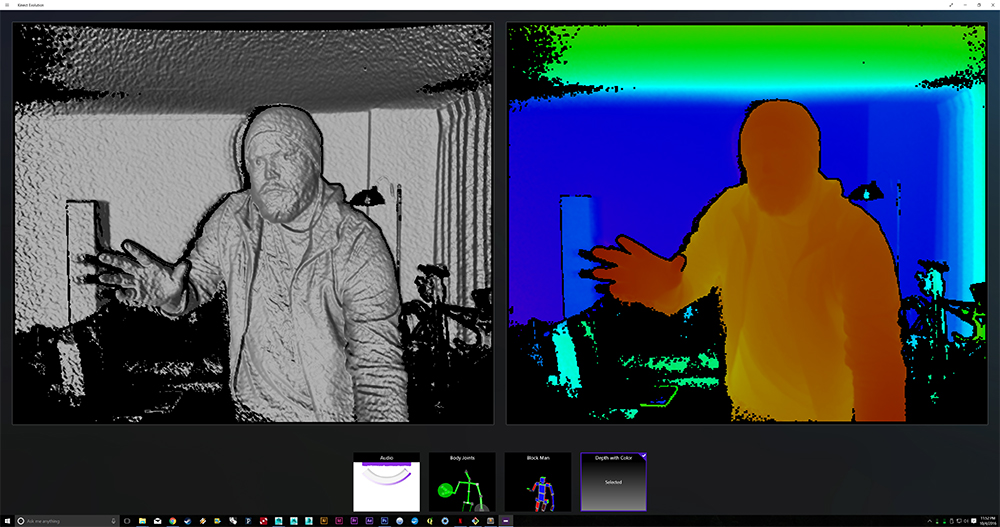

For the 3D Scanning Portion of the Assignment, I took a dive into my Kinect 2. This is the scan info that comes out of the kinect. I used processing and the OpenKinect libraries to extract the pointcloud data. Sadly it doesn't yield as detailed a mesh as I would have hoped, but it turns out the Kinect can be hacked with some polarizing filters and a little bit of code courtesy of MIT. I'll be taking a deeper dive into that in the coming weeks. More to come...