Description:

"Architecture exists at the confluence of form, material, environment, and structure. While this odd set of bedfellows informs architecture, this overlay produces an experience for the occupant.

Microtherme is a condensation of thermal and sensorial experiences that produces contradictions of conventional notions of comfort. Sitting adjacent to a burning fire on a cold night is a

known comfortable experience, yet it does not fall within the ASHRAE standards of the ‘Thermal Comfort Zone’—a rather narrow definition that assumes continuity over difference.

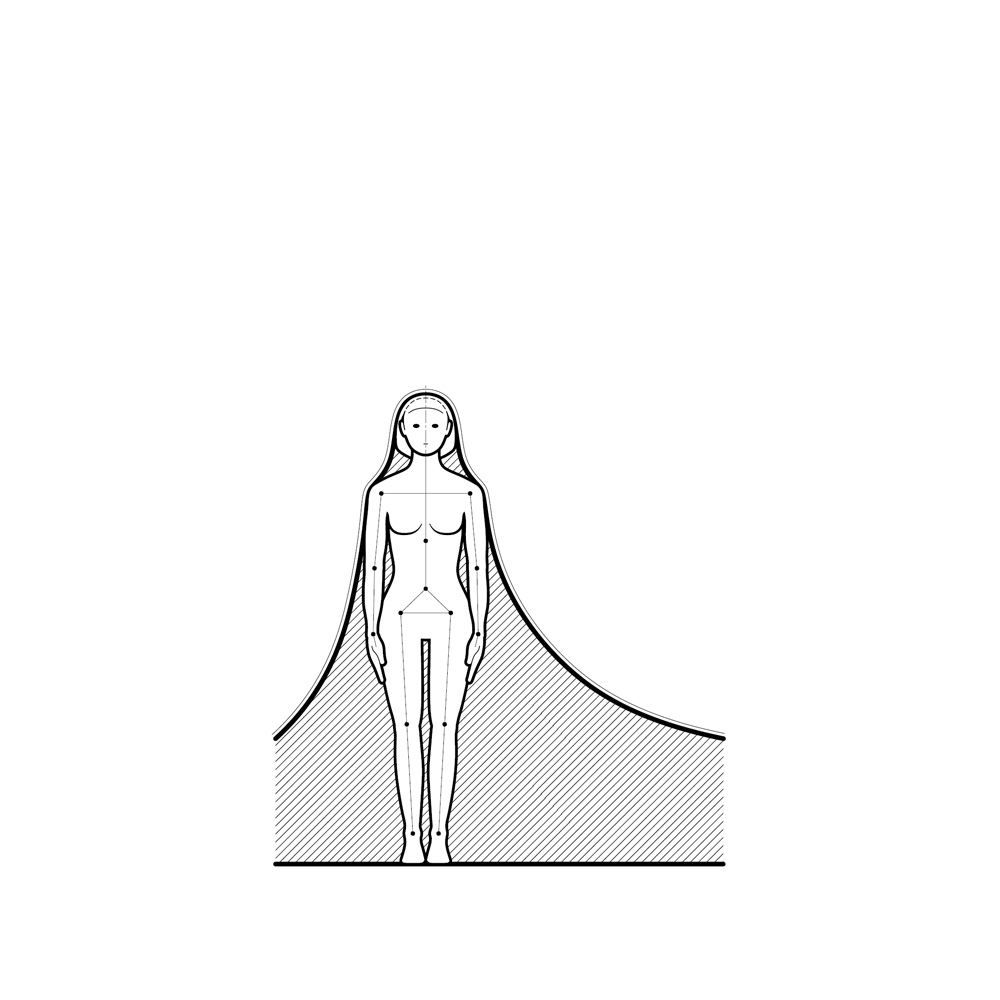

The human body is capable of, if not excited by, thermal extremities. In the conception of the Roman bath complex, occupants move from extremity (caldarium) to extremity (frigidarium),

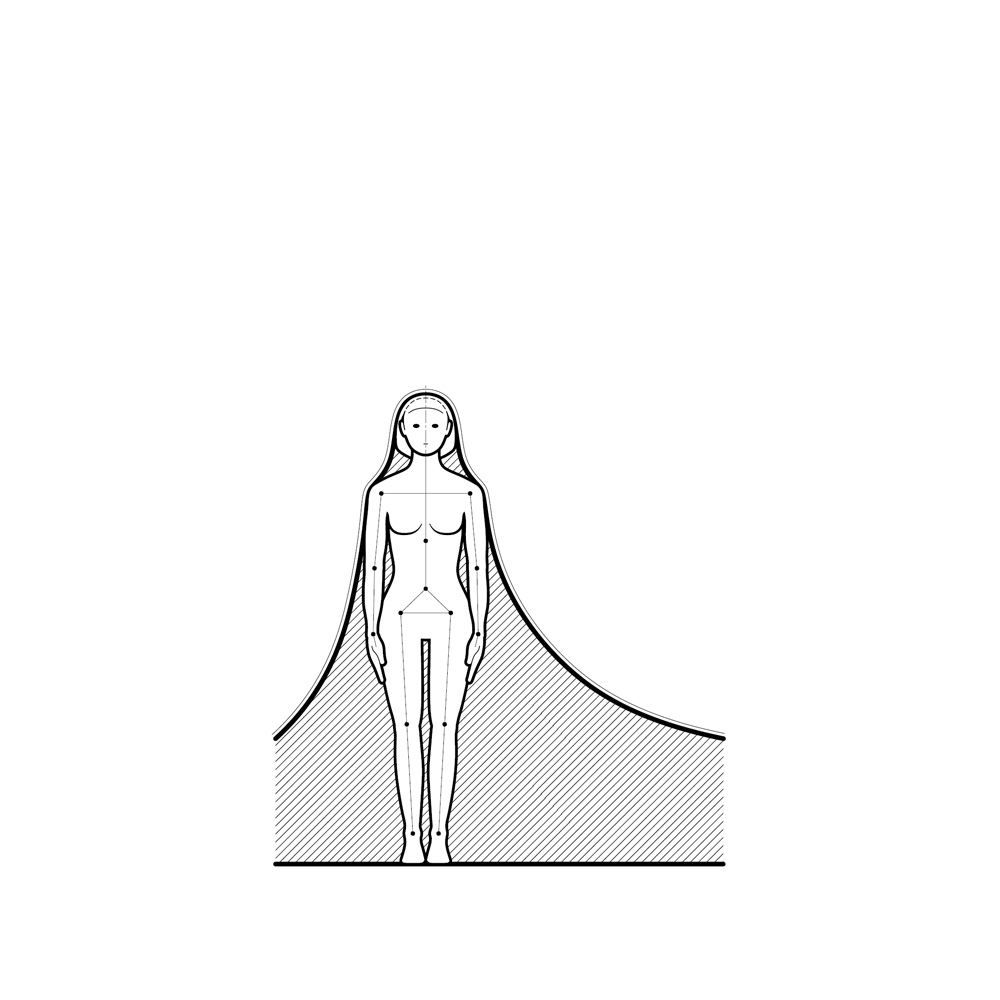

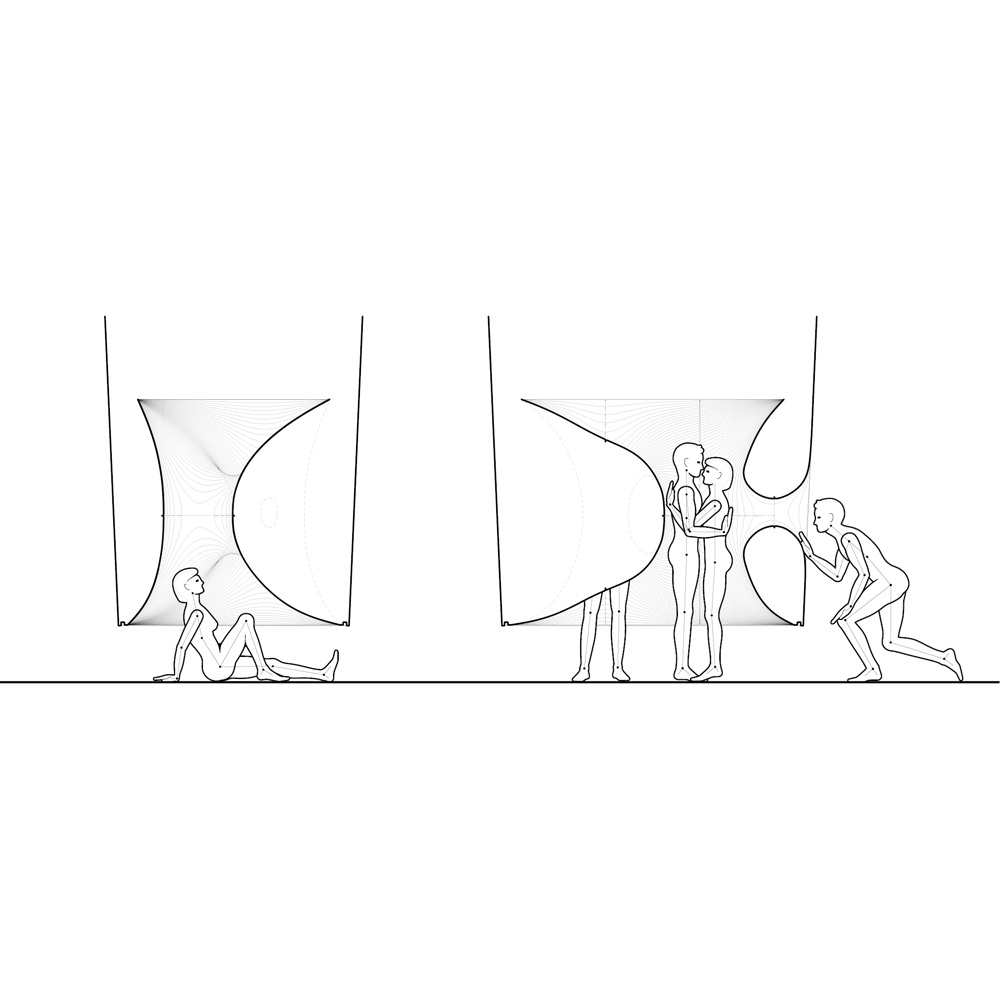

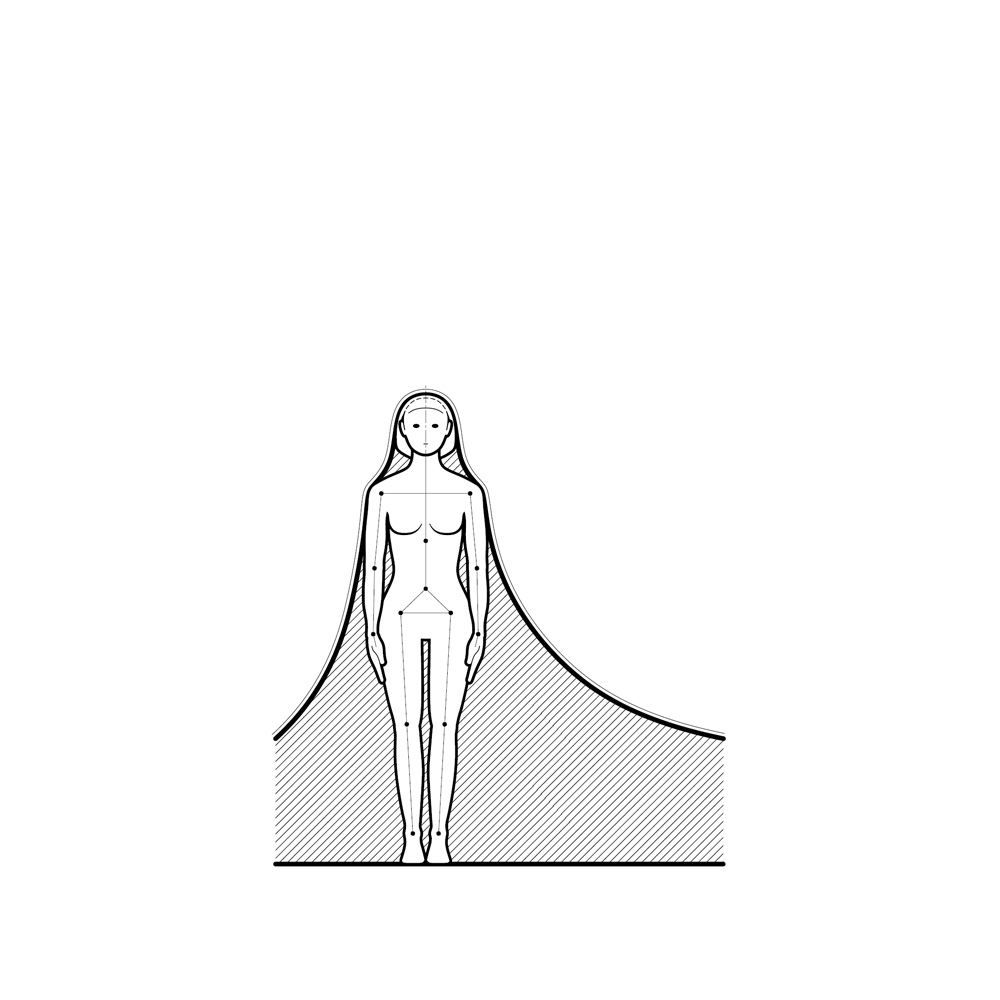

managing their own thermal delight. As opposed to a liquid bath, Microtherme is a radiant one that co-mingles extremities into singular thermal contradictions.

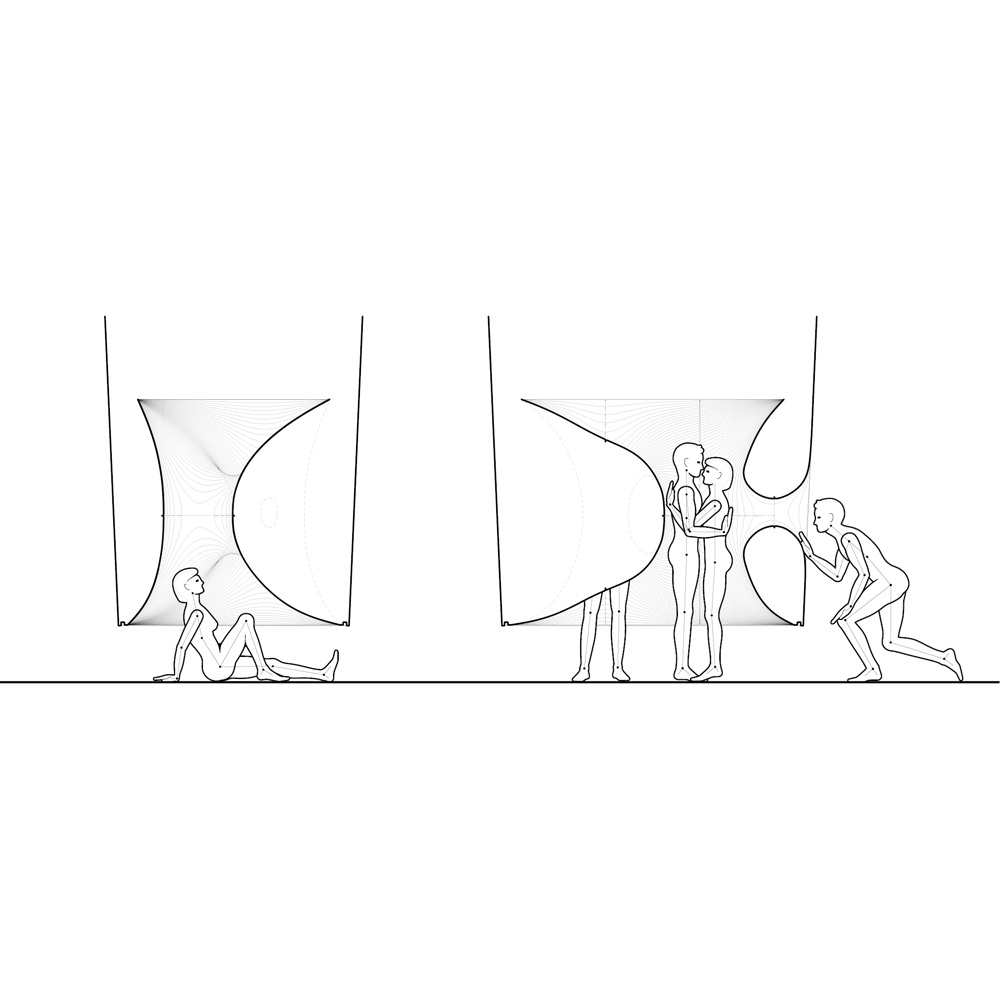

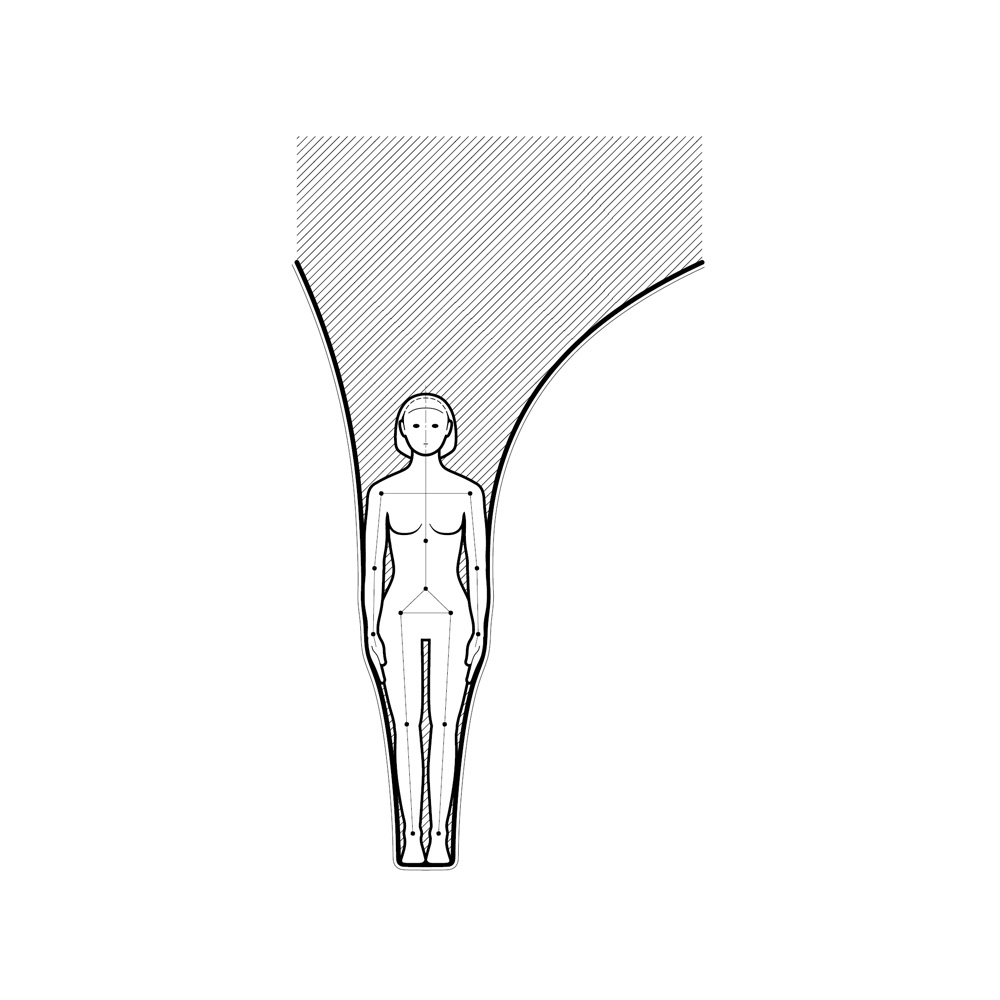

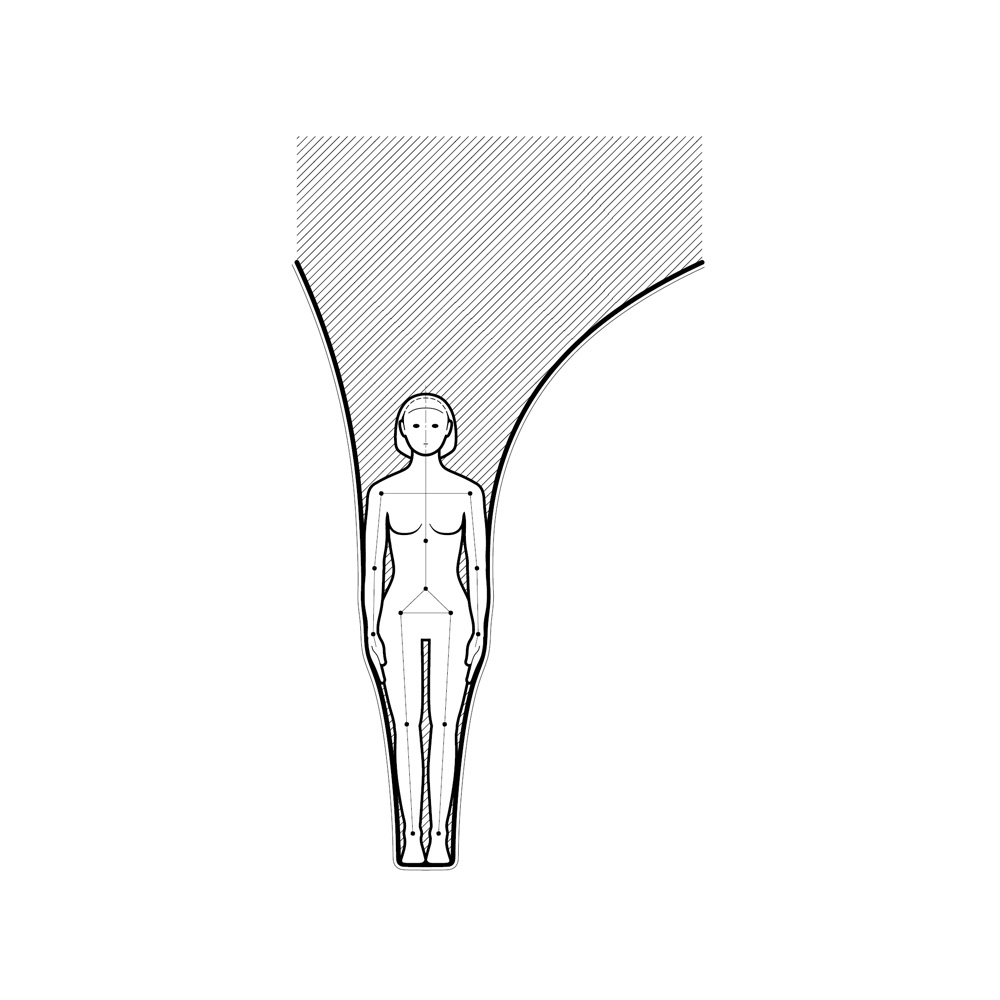

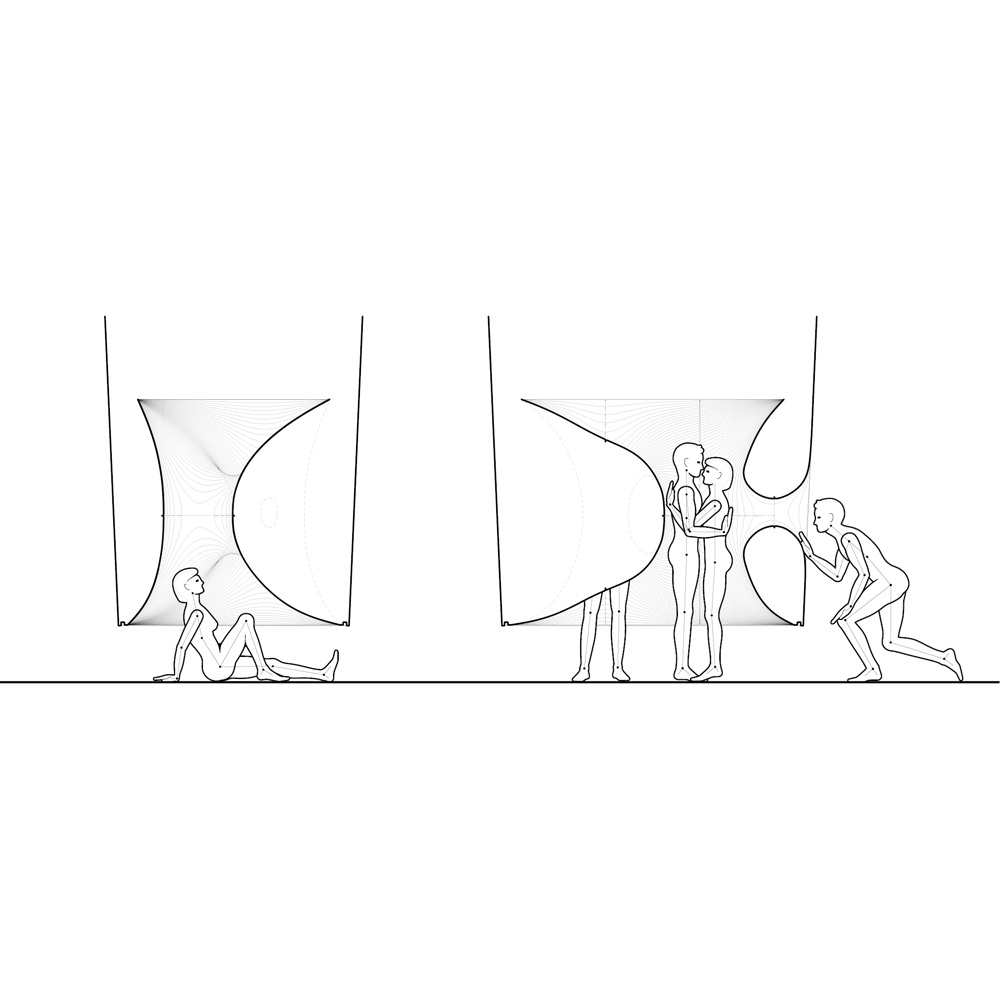

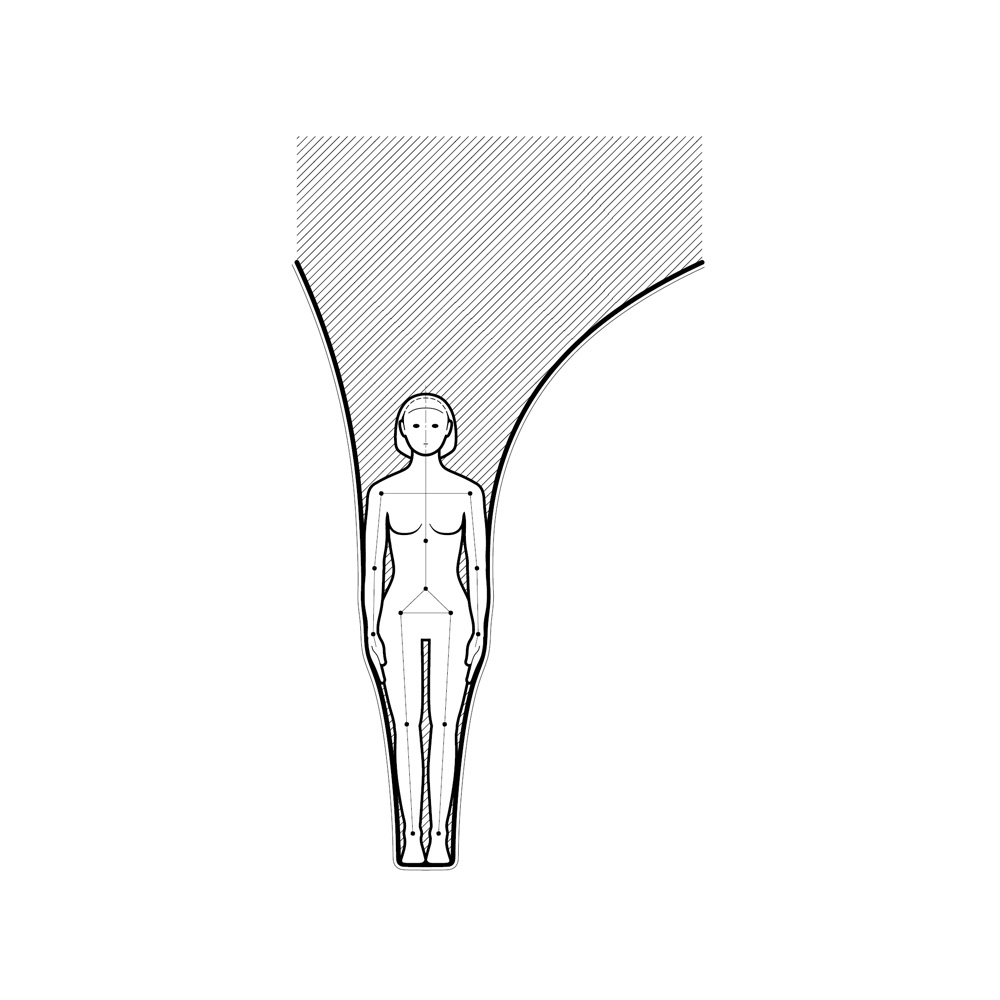

It frames the occupant's experiences from the act of rolling under a monolithic object to standing up inside the bath, the occupant is confronted with another world inside,

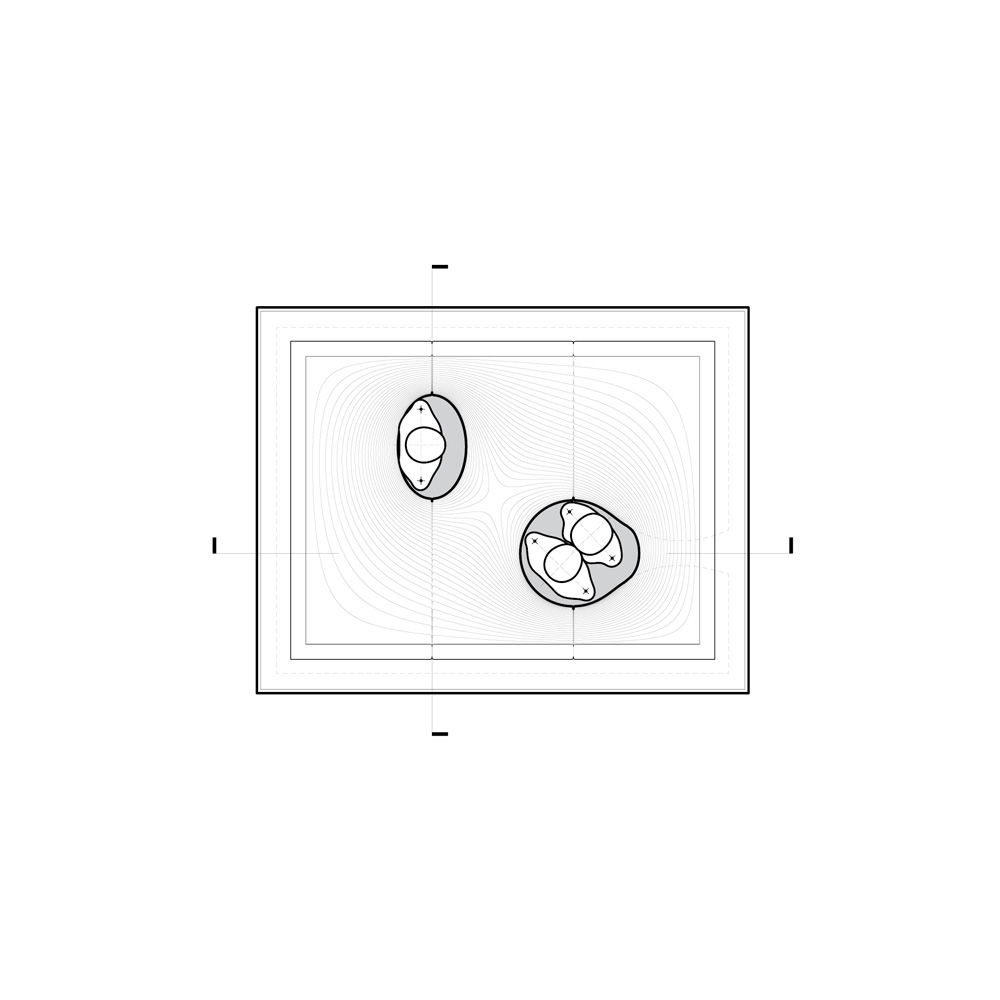

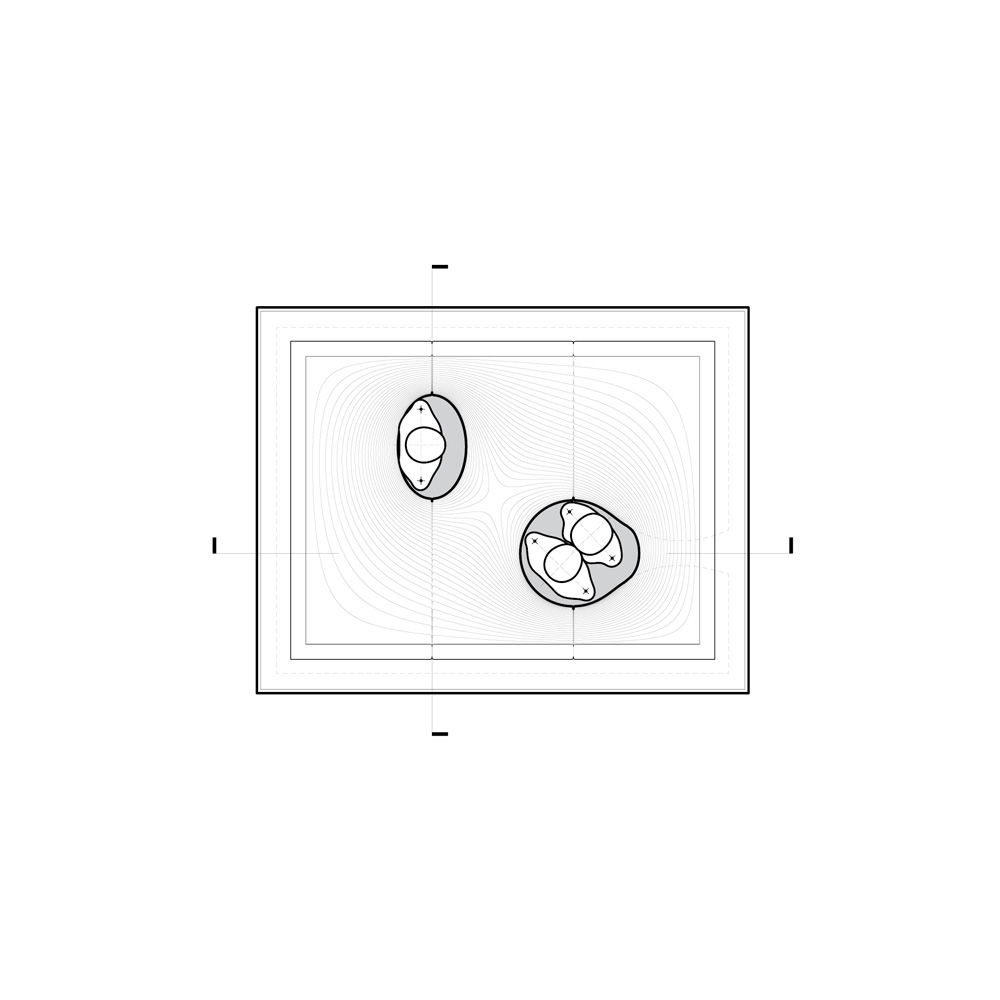

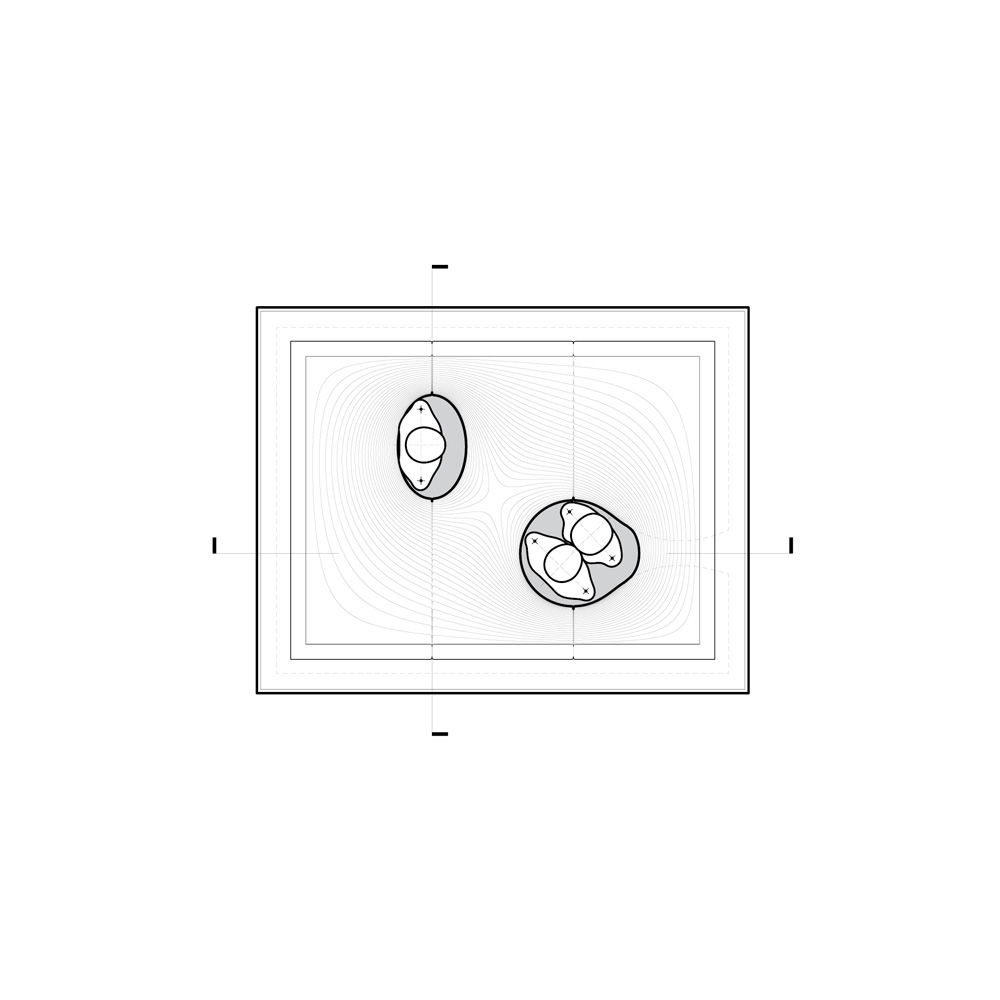

producing the illusion and thermal experience of wading in a bath of voluptuous concrete. Microtherme is constructed from a machined mold of expanded polystyrene (EPS)

foam that is coated in a water based surfacing compound. This mold is cast by spraying Glass Fiber Reinforced Concrete (GFRC) with a lining of copper tubing to allow warm

and cool water to pass through in order to control the temperature of the concrete." - Brandon Clifford